Le Maghreb Newspaper – Gabes, Tunisia – “ I am no longer able to live without it” Fatima complains as she removes the cap of the medicinal inhaler and takes three spurts into her mouth. The same goes for her granddaughter Rahma, 9.

Both suffer from a severe shortage of breath as a result of the poisonous gases emitting from the Chemical Factory compound in Gabes, the sixth largest city in Tunisia and home to several chemical-based industries including cement, bricks and an oil refinery.

Fatima began her journey with the illness in 1979, eight years after the construction of the compound 500 metres from her house in the Shat AsSalam area.

Fatima and Rahma are two of many residents, mostly children and the elderly, who suffer from respiratory illness in the Shat AsSalam. Symptoms of these illnesses intensify when the wind changes direction and comes from the east, turning into ‘’Samawi (Arabic name for poison) winds” as they carry chemical elements coming out of the compound.

There is hardly one home in this area that is free from any sufferer of an illness such as skin allergy, osteoporosis or respiratory diseases like asthma.

This is the conclusion after months of investigating the impact of elements of Phosphogypsum (GP) – a by-product of the production of fertilizer from phosphate rock — coming out of the factory’s filters, on the area’s residents.

“Samawi Curse”

The Samawi curse is what Buthaina Al Talmoudy, 35, fears. As soon as the wind intensifies she fortifies herself with an inhaler of “Asebrol 100” so she can use it for her 11-year-old son Haithem, one of 56 children suffering from respiratory allergies since childhood.

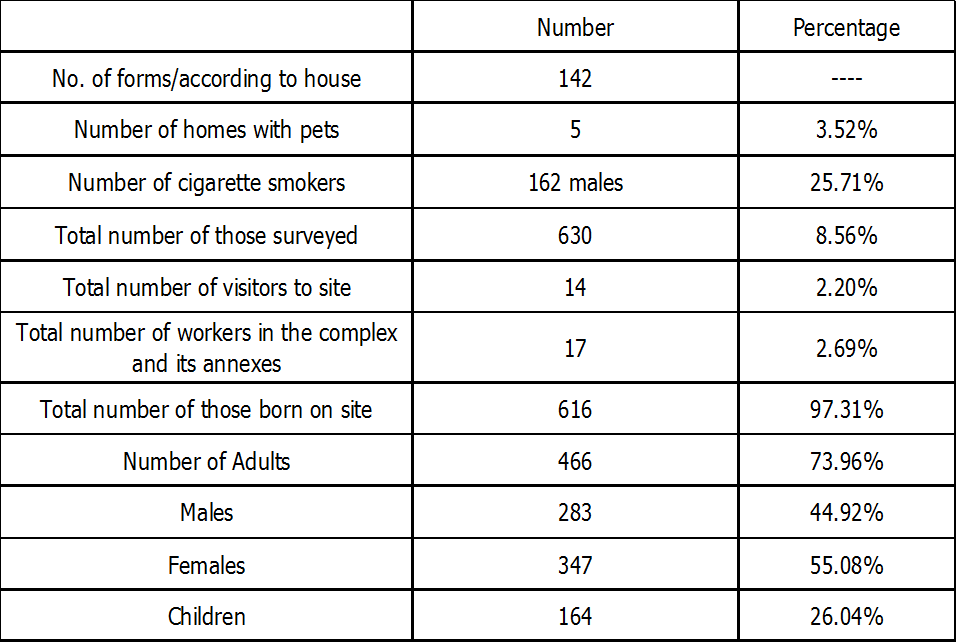

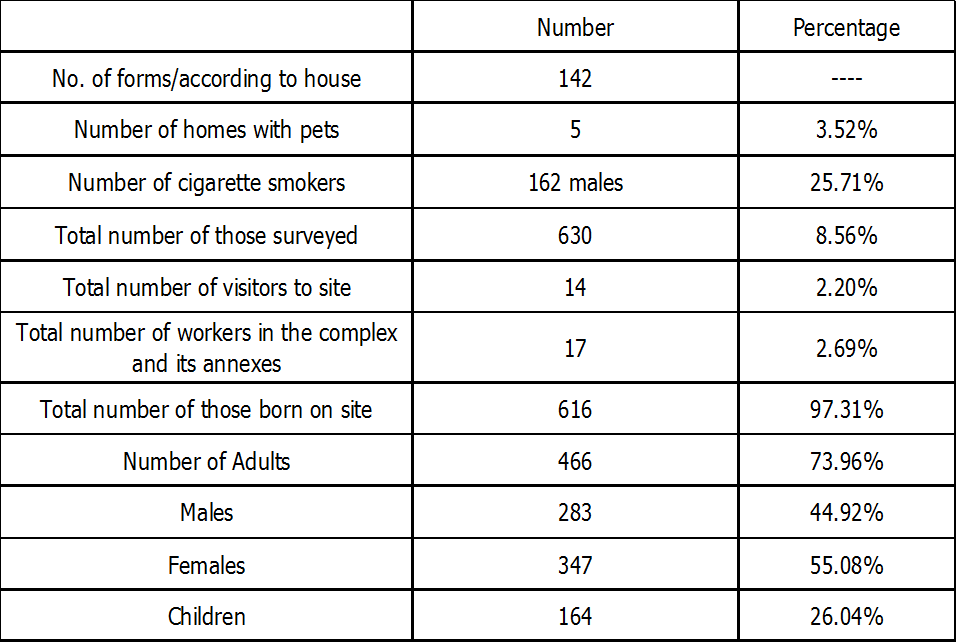

This investigative reporter surveyed 142 houses with 630 residents out of a total 7352 people living there, according to municipal records.

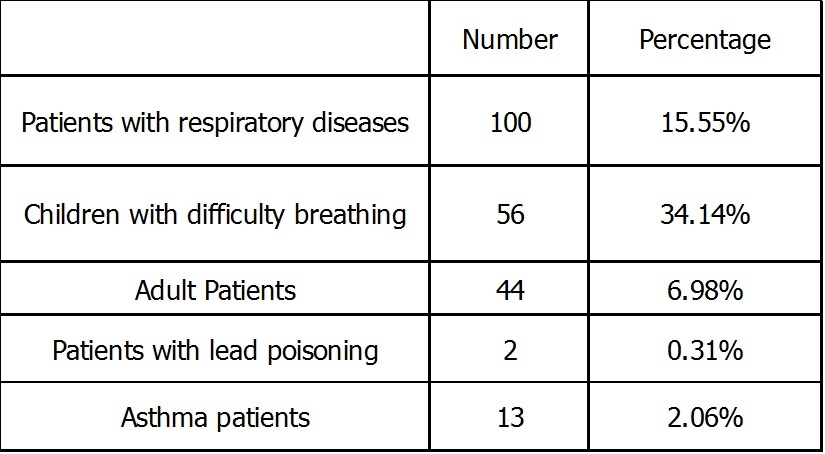

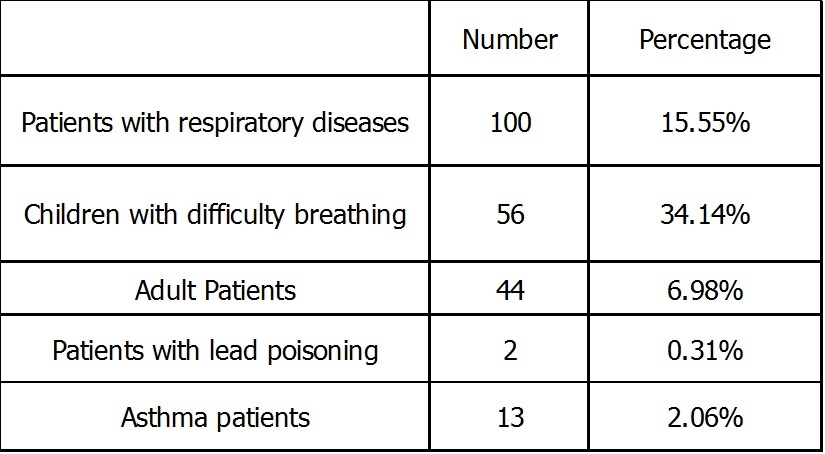

In a questionnaire he distributed, he showed that one in three children in the area suffered from respiratory diseases while 15.55% of those surveyed said they had fallen ill due to elements emitted by the compound’s aging filters.

Gabes in the third governorate at the national level, with 2.3% of residents suffering from respiratory diseases, according to a 1995 study by two physicians from the College of Medicine in Tunisia and supervised by the health ministry. The highest rate was in the governorate of Ariana, with 4.8 residents suffering from similar diseases. Ariana is a leading industrial area with excavation and conversion factories such as cement and oil.

The findings of this reporter in Gabes are six times higher than those found in that study.

The outcome of this investigation also highlights the negligence of the current environment law, which does not enforce monetary fines and other punitive measures including closing down violating establishments. The problem is further compounded by the negligence of the country’s monitoring authorities especially the Departments of Industrial Environment and Soil Preparation at the Ministry of Environment and Sustainable Development. Officials in charge of these agencies cannot fine any violating factory because implementation of the 2010 environment law was postponed until 2016.

Environmental activist Sami Qiza, who carried out a study in 2013 on the factory’s environmental hazards, argues that the lack of policies prior to 2011 aimed at finding a solution for the pollution in Gabes and controlling the poisonous emissions from the chemical compound does not excuse the administration from shirking its responsibilities towards adhering to international standards.

Conflict in attributing the cause

The 2013 study was preceded by another in 1995 by Dr. Fawzi Bali entitled “the accumulative expansion of Asthma in Gabbs and its obvious causes,” which is generally relied upon by the authorities to question any ties between the pollution and the diseases. In his study Dr. Fawzi concluded that cigarette smoking and domestic pets were the primary causes behind the area’s inhabitants’ respiratory allergies, excluding the responsibility of the chemical factory. However, this study which was carried out at “the doctor’s own expense and for private reasons” is still questionable although cited by the authorities in order to avoid paying compensation to victims.

The questionnaire prepared by myself refutes the outcome of this study since most families gave a negative answer when asked whether or not they owned a pet. Those who did own pets – mostly birds or sheep – constituted 0.79% of those surveyed; 41% of those questioned, being women and children said they did not smoke while the smokers amongst men reached 70%.

The Ministry of Justice refuses to reveal the number of cases that have been filed by civilians against the factory since 1992, the date of the first reported case. However it does confirm that the courts of Gabbs (First Instance and Appeals) have not ruled in favour of the plaintiffs in any of the cases.

Losses and Pollutants

The factory’s administration has cited “the difficult financial situation that the compound has been witnessing since (the revolution) 2011” as the main reason for not being able to update production levels and the filtration system to meet international levels.

Since then, according to Najeeb Murabet and Al Zaydi, the compound’s director general, the chemical and phosphate industries factory was pressured into hiring more than 10,000 employees reaching a total number of 14,000 — though the factory only required 4,000 to operate it.

In 2010, the fertilizer and phosphate sector was bringing into the country profits of almost 850 million dinars ($540 million) annually. These numbers decreased due to lack of security, reaching losses estimated at around 3 billion dinars ($1.8 billion) in 2011, 2012 and 2013, according to documents from the Ministry of Industry and the Tunisian chemical compound. This was caused by wasted returns due to the compound’s inability to meet commitments.

According to a factory employee, these wasted returns, caused by administrative flaccidity, led to the suspension of funds specified for upgrading the equipment. He also refused to reveal the overall amount of salaries paid by the compound despite being provided with evidence indicating that salaries exceeded 140 million dinars ($90 million) annually — one third of the factory’s expenses.

The director-general explains that installing two units and modernizing the filtration system, as well as washing the dual chimneys will cost $400 million, which is $130 million more than the total annual expenses, including salaries.

He confirms that the filtration system and the equipment that was installed since the establishment of the factory in 1971 were out-dated and no longer productive.

It operated on a “unitary suction” system that disposed the Phosphogypsum into the sea, or stored it in “an organized space”.

According to a factory employee the administration introduced the dual suction system in four of the six chimneys starting in 1994. He also mentioned the delay in implementing an environmental rehabilitation program – which was supposed to go into effect in 2013. The program is intended to cleanse the ammonia gases and limit the sulphur dioxide emissions in two of the industrial units at the chemical compound.

Respiratory diseases specialist Dr. Samira Mari’ee considers “Sulphur Dioxide SO2” inhalation the main cause of the area residents’ illnesses since this gas can cause damage to the respiratory system as well as the lungs, leading to coughing, mucus, asthma and chronic inflammation. Hence, victims become more prone to infection.

According to a report by the World Health Organization entitled “ the World Health Organization’s Guide to Air Quality…Latest International Standards for 2005, “ this gas is the cause of many hospitalizations due to heart diseases as well as a rise in mortality rates especially during periods when Sulphur Dioxide levels are high.

Recalling the Gas Leakage

Amongst the chronically ill is Rahma Al Talmoudy, who has been suffering since the age of three from respiratory allergies making her reliant on her inhaler at school, at home and in the playground, as her father informs us. The 20 meter house yard is the extent to which she can go as she is not permitted to be out of the sight of adults. This is because she might suffer a shortage of breath episode requiring assistance.

The family still recalls the 2008 incident when chemical gasses escaped from the factory chimneys and tens of Shat AsSalam residents had to be taken to hospital suffering from gas inhalation caused by the Ammonia and Sulphur Dioxide gases.

The injury rate is also high amongst women with 68,93% adults suffering from respiratory illnesses, that is 29 individuals or 4.6% of the subjects surveyed.

Rawya Al Farji, 36, is one of the women who has been suffering from an illness in her respiratory tract for 13 years and since then has been reliant on her “Asebrol 100” inhaler which was prescribed to her by the doctor to combat the shortness of breath episodes which happen on average eight times a day. She had to be hospitalized on two occasions every month as a result of asphyxiation; she says. “ I live in fear of the Samawi winds”.

Look to the Chemical Compound

The chemical industries compound releases white smoke from its chimneys. They are between 25 and 70 metres high and have a 2.2 meter circumference, according to Abdul Razak Al Thabity, director of the contracting and maintenance company which built the chimneys and supervises them.

The residents of the area call the white smoke emitted by these chimneys as“steam”. The smoke includes Sulphur Oxide SO, Sulphur Dioxide SO2, Nitrogen Oxide NO, Ammonia NH3 and Hydrogen Fluoride HF.

According to Yousef Al Zaydi, deputy-director of the Industrial Environment Department at the state Agency for Sustainable Development — formerly the Ministry of Environment – Sulphur Dioxide emissions are created by the activities of the compound which consists of six industrial units producing phosphate by-products such as fertilizers.

As an explanation to why the state agency did not fine the chemical compound, as part of its monitoring duties, Al Zaydi sees this infraction as temporal depending on the climate. In 2010, a directive was issued to limit the levels of pollution from the source. It was supposed to go into effect in 2013 but this was postponed until 2016, according to Al Zaydi. The three supervisors charged with monitoring the compound have a simple duty of only measuring the pollution levels and comparing them to international standards set by the World Health Organization

Once the law goes into effect in 2016, the agency will have the authority to impose fines, to be determined later, or close the offending unit if it did not adhere to the regulations or to the issued warning.

The law in effect today is Law No. 34/2007 issued on June 4th 2007 and dealing with the air quality. It gives violators a grace period – three years to maintain equipment and adhere to specifications – without issuing any monetary fines. The amended law would require industrial institutions to respond to pollution limits or else face the risk of immediate closure or fines.

Al Zaydi believes that postponing the implementation of the new directive in 2013 was due to the inability of setting limits for the above issues “because of a number of reasons, the main one being that the country after the revolution was going through an economic and financial crisis.

Conflicting Explanations

Every year the state Agency for Sustainable Development admits to the increasing levels of pollution in Gabes without providing any benchmarks for acceptable national levels. Al Zaydi has refused to discuss increasing levels of pollution saying that there is an increase” in Ammonia and Sulphur Dioxide gasses as well as dust at certain times, “depending on the climate.”

Chart One (Form Schedule) General Information on subjects

Health conditions schedule according to questionnaire

Al Zaydi says the direction of wind has an effect on “polluting the air.”

However, the chemical compound has six chimneys “two of which do not adhere” to national specifications in “emitting gasses.” The first chimney emits approximately 200 grams/tonne of Ammonia gas, four times the permissible national level of 50 grams/tonne; in direct opposition of what Al Zaydi calls “a slight increase.”

As to the Sulphur Dioxide emissions, it reaches 13 kilograms/tonne, which is 65 times more than the permissible national level (200 grams/tonne). This data is given by the director of the environment unit at the Chemical compound in Gabes Noureldin Al Tarabulsi, who also admits to the emissions and other foul smelling gasses such as Fluorine.

World Health Organization Specifications

– Nitrogen Dioxide (NO2: 40 micrograms/m3 annual average and 200 micrograms/m3 average per hour.)

– Sulphur Dioxide (SO2: 20 micrograms/m3 average per 24 hours and 500 micrograms/m3 every 10 minutes)

“The Steam”

Families and residents have sad stories regarding the chimney “steam”. One such tale involves an explosion in the Ammonia releasing chimney. The first incident took place in 2008 and the second on February 5, 2013; both led to many residents of Shat AsSalam being taken to hospital suffering from asphyxiation. The principal cause of these injuries was the release of Ammonia (NH3) gases from the chemical compound. This highly concentrated gas, more than 40 grams/tonne (acceptable international levels are 10 grams/tonne less than Tunisian ones) aggravates the respiratory tract especially in those with respiratory illnesses.

Destroying Paradise

Prior to the establishment of the chemical compound on the coastal beaches in 1971, the Gulf of Gabes was regarded as a “paradise”. Today, the environmental damage is visible. The phosphate treatment plant has been dumping phosphogypsum in the Gulf for four decades, at a rate of 13,000 tonnes per day. This information is confirmed by Noureldin Al Tarabulsi, head of the environment unit at the factory.

Tarabulsi, like the country’s agency of Sustainable Development –formerly the Ministry of Environment, believes that this substance has no harmful effect on the environment.

However, the Ocean Protection Society in Gabes has a different outlook. Relying on the radiation tests to prove that Phosphogypsum is a “killer”, it says that radiation rate of the phosphogypsum reaches 4.2 particles per million. This has led to a large area of Phosphogypsum forming in the sea – one that is filled with phosphoric acid with a concentration of 200 grams/tonne and reaching 60 km2. The thick layer of PG can be seen via satellite images.

Noureldin Al Tarabulsi as well as the director general of the compound Najeeb Murabet and Al Zaydi, director of Industrial Environment agree that dumping the phosphogypsum in the sea pollutes the beaches. They say that such a method of disposal was acceptable in the seventies and eighties because no other solution was available.

Al Zaydi also confirms that the polluted area of the sea is estimated at 40 hectare with varying degrees, including Fluorine pollution as well as other heavy meals such as Lead and Cadmium. But none confirm or deny that such substances can have an adverse effect on human health.

Al Zaydi ties health concerns to the time of “pollution exposure” including the levels and concentrations of these substances.

Reem Bin Omar, assistant university professor at the College of Sciences in Tunis and researcher in geology puts forward the results of a scientific research that she has worked on since 2003. She has recorded high levels of Cadmium, between 2 and 59 particles per million, surpassing the French specifications which considers any Cadmium levels above 2.4 particles per million as an indicator of pollution.

She has had to compare the results with the French standards because there are no Tunisian specifications. According to Bin Omar, the most obvious sea pollution indicators are being recorded in the area between the fishing port and the industrial port more specifically the location of Shat AsSalam is where levels of Fluorine reach the highest levels of 8.633 mg/litre and an average of 12.9% in the seabed.

Everyone acknowledges the pollution levels and awaits studies

All the official sources including the Ministry of Industry, Energy and Mining, the Chemical Compound, the Agency for Sustainable Development and the Ministry of Health agree that “pollution in Gabes is a real concern,” although somewhat “exaggerated”. However , when asked about the effects of this pollution on human health they all replied that they agreed with Ministry of Health in 2011 to carry out studies that would prove the effects of the pollution on the residents’ health.

The Ministry of Health affirms that it will put together a medical team to carry out studies but officials refuse to discuss the effects of the pollution or provide statistics.

Transferring the Phosphogypsum

The Ministry of Industry and the Chemical Compound in Gabes, which falls under its jurisdiction, plan to explore a project to transfer Phosphogypsum to a dump in the area of Al Mukhashrama, in the governorate of Wathraf. Noureldin Al Rashidi was appointed director and in 2013. He issued a memorandum of guidelines and published international requests regarding the establishment and execution of the phosphogypsum landfill.

This project includes technical aspects, one of which is the transferal of the Phosphogypsum mixed with industrial water through plastic pipes placed inside metal cylinders such as those used for the transferring of petrol; enforcing high international standards to ensure rigid specifications. The water table would also be protected from any leakages by preparing the landfill in accordance with international standards. The bottom of the dump would be covered with an insulating material made of rubber and a layer of Bentonite over an area of 50 hectares surrounded by 100 metres of trees.

This new vision for removing the Phosphogypsum was first announced by Abdul Rahim Al Zawari, former ministr of transport in July 7, 2006. This was part of the “the project to end sea pollution” in Gabes. The minister said that the material would be carried by “rail” and that this would be done “as soon as possible” adding that the project also involved rehabilitating the rail network and fortifying the lines between the production units in Gabes and the Ganoush station, as well as preparing and consolidating the network between the two stations at a distance of 23 km; this project however fell through.

Cadmium on the line

The Phosphogypsum curse does not end with the pollution that it creates or the phosphoric acid it contains which causes unknown radiation levels.

Add to that a new element known as the “catalysateur” which is what the workers at the chemical compound call this chemical catalyst that is used to speed up the process of Sulphuric acid. It is imported by the company “Mecs Global” with a warning label attached on its products citing hazards to health such as eye, skin and respiratory inflammations and dangers if swallowed or inhaled repeatedly and for long periods of time leading to lung damage.

This substance is disposed of in an industrial dump in Gabes used for the storage of Cadmium. Officials at the chemical compound insist that the methods applied are legal and adhere to specifications. It is piled in the shape of dunes so as not to spread in the air. The area is also insulated with a layer of plastic placed on the ground so that the material does not seep through. This new landfill was created in 2011 after the closure of the “Grado” recycling centres, where refuse was sent. Yousef Al Zaydi says that this dump was licensed by the Ministry of the Environment and is temporary and isn’t harmful to the environment. It will not be permitted to remain for long as it can pose a threat to human health and to the environment.

Medical Files

In addition to the questionnaires, I investigated a number of medical files at the local hospital in Shat AsSalam to study the effects of pollution on the resident’s health.

After studying 394 files I found that doctors were making a connection between the respiratory diseases and the pollution in the area. There were 26 asthma patients at the local clinic in Shat AsSalam, around 6.59% of the residents registered there and of both sexes. There were 20 male patients making up 76.92%; 50% of the patients were of the ages between 30 and 50.

This investigation was completed with support from Arab Reporters for Investigative Journalism and coached by Saad Hattar.

Leave a Reply